In today’s evolving agricultural landscape, maximizing forage quality is more important than ever—especially for livestock farmers aiming to boost productivity and reduce feed costs. While dry hay remains a staple, more farmers are turning to haylage as a reliable and nutritious alternative.

But what exactly is haylage, and how is it made?

Let’s break it down.

What Is Haylage?

Haylage is a type of preserved forage made from grasses or legumes that are partially dried and then fermented in airtight conditions. Think of it as the middle ground between dry hay and silage. Unlike dry hay, which is fully dried, haylage retains more moisture—around 50% to 65% dry matter.

This moisture level allows beneficial lactic acid bacteria to ferment the forage, producing acids that preserve it. The result? A moist, palatable, and nutrient-rich feed with less dust and greater digestibility, especially beneficial for dairy cows and other livestock.

Why Choose Haylage?

Better Nutrient Retention: Because it’s not over-dried, haylage retains more proteins, energy, and vitamins.

Improved Palatability: Animals often prefer the taste and texture of haylage over dry hay.

Processing haylage successfully requires more than just basic knowledge—it demands precision, timing, and the right tools.

That’s exactly where AgriProExcel steps in.

Our goal is to ensure farmers get the highest feed quality, reduce spoilage, and maximize livestock performance—all while making the process more efficient and climate-smart.

The Haylage-Making Process

Here’s a quick overview of how haylage is made:

1. Cut the forage at its peak nutritional value.

2. Wilt it in the field until it reaches 50–65% dry matter.

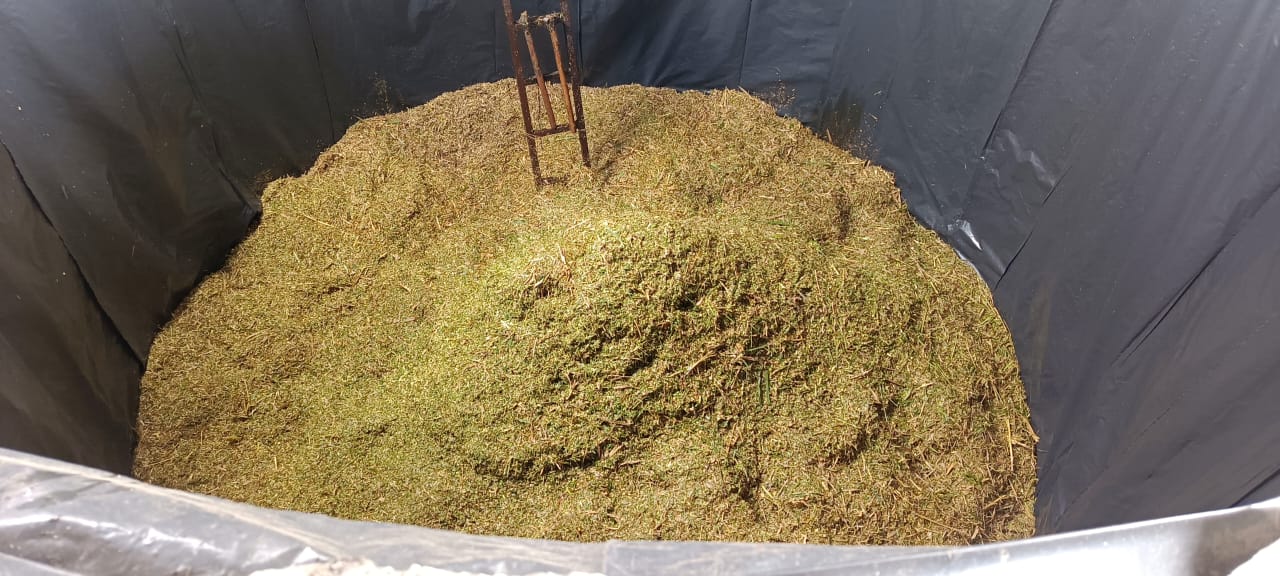

3. Bale or chop it quickly once the right moisture is achieved.

4. Seal it airtight using plastic/Polythene wrap or airtight bags.

5. Allow fermentation for 3–6 weeks before feeding.

Haylage vs. Dry Hay: What’s the Difference?

The major difference lies in moisture content. Dry hay is fully dried to around 85–90% dry matter, preventing fermentation. Haylage is preserved through fermentation, due to its higher moisture content.

Leave a Reply